rockwell and brinell hardness test experiment|difference between rockwell and brinell : member club The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials.

webTheuzin: albums, songs, playlists | Listen on Deezer. Sign up for Deezer for free and listen to Theuzin: discography, top tracks and playlists.

{plog:ftitle_list}

web19 de jan. de 2023 · 1.1M views 3 months ago. This is tutorial how to unlock Chiku scene in patreon version 0.16Game is available on the FATAL FIRE Studios patreon - .

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

(III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.This experiment will include Brinell, Vickers and Rockwell tests which measure resistance to penetration. The amount of deformation that occurs when a small, hard steel ball or diamond .

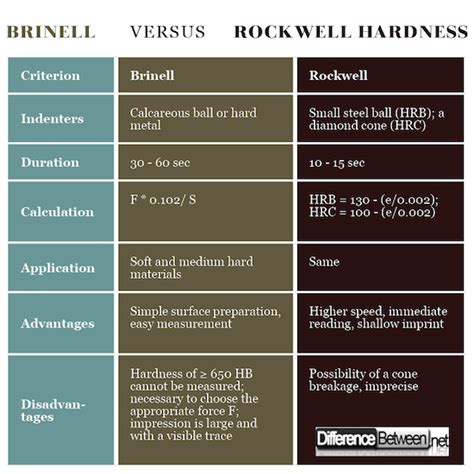

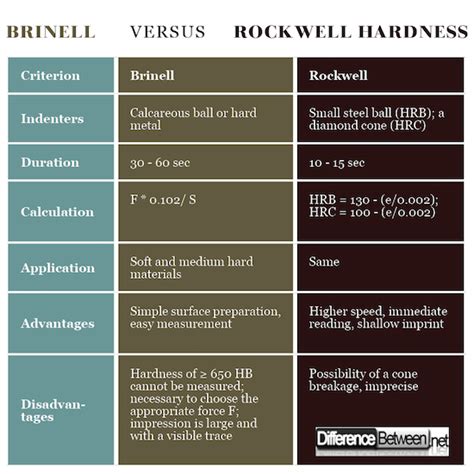

Rockwell testing differs from Brinell testing in that the Rockwell hardness number is based on an inverse relationship to the measurement of the additional depth to which an indenter is .

Through experimental measurements and finite element modeling of various types of materials, we show that Rockwell hardness and Brinell hardness are closely correlated .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials.Rockwell hardness test. Use ASTM E 140-88 "Standard Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, .

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Harder materials will generate shallow indentations while softer materials will produce .ME 212 LABORATORY EXPERIMENT #3 HARDNESS TESTING AND AGE HARDENING 1. OBJECTIVE: . depth of indentation provides a measure of hardness. The Rockwell, Brinell, Knoop, Vickers, and ultrasonic hardness tests are of this type. For engineering purposes, only the static indentation tests are used. .

To record the results during the experiment of each test we conduct for later calculations. Objectives: • • • Write a report on Hardness testing using two methods Rockwell and Brinell and describe them using different headings .The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens . Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5. Abstract. There exist various types of experimental measurement of hardness, yet a unified understanding of various hardness measurements lacks. Here, by testing the hardness of a wide range of materials, we show that Rockwell and Brinell hardness tests, the two most used hardness measurements, are closely related. The experimental .

rockwell vs brinell hardness test

Superficial Rockwell hardness test: In this test, a load of 15, 30, or 45 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds.Duration of Brinell and Rockwell Hardness; The Brinell test is very slow (30 – 60sec). Rockwell’s test is shorter (10 – 15sec). Calculation of Brinell and Rockwell Hardness; Brinell’s Hardness (HB) is the ratio of the applied force F (N) and the surface of the fingerprint S (mm 2): HBW = (F*0.102/ S); S = π* D* h. Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition . What is Rockwell Hardness? Similar to Brinell hardness, Rockwell hardness is also used to understand what the hardness of material is in numerical terms. This is done through the use of a Rockwell hardness test and a Rockwell hardness scale. The exact method can be found in ASTM E18.

рубанков нет влагомер

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.Conclusion: The hardness test experiment was done using a Brinell and a Rockwell Testers. The data obtained was recorded and compared. The experimental and referenced values for each metal were compared. Table 2 showed that the percent differences for Rockwell Test were smaller than for the Brinell test. This concludes that the Rockwell test is .

BRINELL HARDNESS TEST: Brinell hardness consists in forcing a steel ball of diameter D under a load P into the test piece and measuring the mean diameter d of the indentation left in the surface after removal of the load. The Brinell hardness is obtained by dividing the test load P by curved surface area of the indentation.

рфьф влагомер

disadvantages of rockwell hardness test

Samples will be selected to be tested by Brinell, Vickers and Rockwell hardness test, the results are given to students in the class lab. a) For Brinell experiment, student has to calculate the BHN and depth of impression (h) through the following formulas for each material tested:ME 212 LABORATORY EXPERIMENT #3. HARDNESS TESTING AND AGE HARDENING . 1. OBJECTIVE . Our primary aim is to measure the Rockwell Hardness values of materials and estimate ultimate tensile strengths by the aid of conversion tables. We will also focus on age . Rockwell testing differs from Brinell testing in that theThe commonly used tests for hardness are: (a) Brinell hardness test (b) Vickers hardness test (c) Rockwell hardness test (d) Rebound hardness test (e) Scratch test In the experiment, Brinell hardness test was used in attempt to .

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . Common indentation hardness scales are Brinell, Rockwell and Vickers. See also: Hardness

The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .Learrn more about hardness testing basics here. The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings.These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .

All information about Brinell hardness testing Test procedure Sample request for the Brinell method Brinell hardness Discover now. . The process is slow (by comparison with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen.

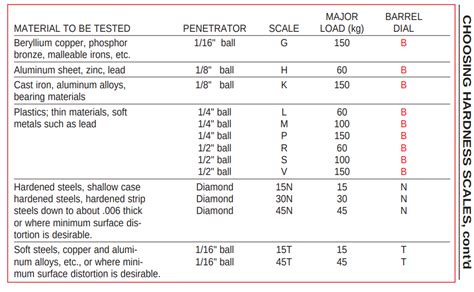

The Rockwell hardness test was invented in 1914 by Hugh and Stanley Rockwell. It measures the hardness of materials by applying two loads with an indenter and measuring the depth of penetration. There are different Rockwell scales that use different loads and indenters depending on the material being tested, such as scales for metals, plastics .The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .

The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. . Rockwell hardness testing is performed with an indenter of a specified size applied with a specified force for a fixed amount of time. A small Tungsten steel ball (HRBW method) is used to penetrate . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests.

difference between rockwell and brinell

webCaso alguém já esteja utilizando seu CPF, telefone ou e-mail como chave, você pode solicitar um serviço de revindicação de chave, normalmente todas as instituições tem está opção dentro de seus gerenciadores, o processo leva em torno de 7 dias. Ferramentas Relacionadas. Utilize nosso gerador de chave aleatória para uso no Pix.

rockwell and brinell hardness test experiment|difference between rockwell and brinell